17758013020 Chen Chen

-

-

-

17816169069 Jinglin Jian

-

17758013020 Chen Chen

17816169069 Jinglin Jian

Professor Fengwei Huo has been a professor at Nanjing Tech University (NanjingTech) since 2014, and currently, he is the standing vice director of Jiangsu National Synergetic Innovation Center for Advanced Materials at NanjingTech.His research focuses on the development of flexible electronic materials, devices and systems, as well as the development of porous coordination polymer based composite materials, etc. Prior to joining NanjingTech, Prof. Fengwei Huo obtained his B.S. and M.S. degrees from Jilin University in China in 1999 and 2002, respectively. He completed his Ph.D. with Prof. Chad A. Mirkin at Northwestern University in US in 2009. Then he joined the School of Materials Science and Engineering in Nanyang Technological University (NTU) as an assistant professor. Up till 2023, Prof. Fengwei Huo has published over 190 SCI papers, including Science、Nat. Nanotechnol.、Nat. Chem.、Nat. Commun.、Adv. Mater.、Angew. Chem. Int. Ed. with over 14,000 citationsand an h-index of 61; he also holds 19 China patents.Currently, he serves as the Associate Editor of ACS Applied Materials & Interfaces and is on the board of journals including ACS Energy Letters and Research.

Design and Application of Leather Electronics

Fengwei Huo*#

# Key Laboratory of Flexible Electronics (KLOFE), School of Flexible Electronics (Future Technologies), Institute of Advanced Materials (IAM), Nanjing Tech University

Abstract

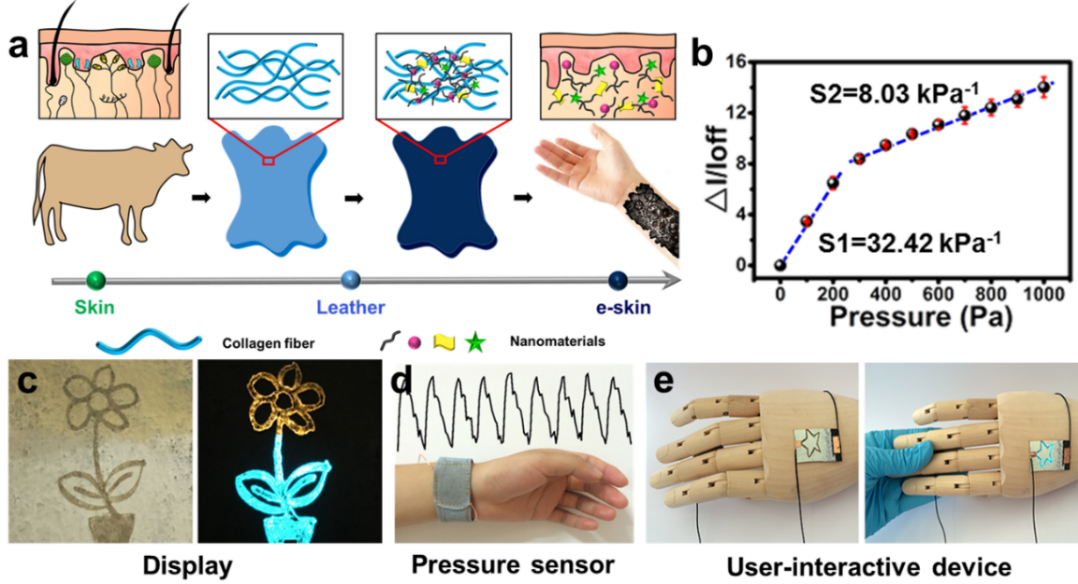

Leather is a traditional natural material which permeates each and every aspect of our daily lives from the coats we wear, to the handbags we carry, and to the covers of books we read. Traditional leather industry recovers the flexibility of skin, while its sensing capability is still under deprivation, an important function of real skin. Leather, animal skins that have been treated with physical and chemical methods, inherits perfectly the sophisticated structure from the skin. Such unique hierarchical structure provides a guarantee for loading other functional materials, promising its potential to prepare high-performance flexible electronics. Based on the above, our group have been exploring the application of leather in flexible electronics by utilizing the advantages of leather such as the natural hierarchical structure, excellent biocompatibility and wearing comfort. Furthermore, the concept of “leather electronics” was proposed by our group when combining leather with various types of functional materials to develop pressure sensors, stress sensors, wearable light-emitting devices, heating devices, and color-changing devices with excellent performance. Those leather electronics re-endow leather with sensing capabilities to mimic or even outshine the performance of real skin. In particular, automotive flexible electronics are currently a research hotspot in our group in an effort to providing solutions for the intelligent automobile field. We dedicate to the investigation of flexible electronic materials and devices systems integration-intelligent realization of automotive cockpit for real-time monitoring of users’ health, cabin environment, etc., so as to realize intelligent human-computer interaction in the automotive cockpit. The preparation process of leather electronics is easy, universal and combinable with traditional leather treating technique, which is conducive to achieving low-cost mass production, and is anticipated to promote the industrialization of flexible electronics.

Figure 1: Leather electronics in pressure sensing, display and human-computer interface devices.

References

[1] Zou, B.H.; Chen, Y.Y.; Liu, Y.H.; Xie, R.J.; Du, Q.J.; Zhang, T.; Shen, Y.; Zheng, B.; Li, S.; Wu, J.S.; Zhang, W.N.; Huang, W.; Huang, X.; Huo, F.W.: Repurposed Leather with Sensing Capabilities for Multifunctional Electronic Skin. Advanced Science, Vol. 6, No. 3, pp. 1801283, 2019.

[2] Zhang, K.; Kang, N.W.; Zhang, B.; Xie, R.J.; Zhu, J.Y.; Zou, B.H.; Liu, Y.H.; Chen, Y.Y.; Shi, W.; Zhang, W.N.; Huang, W.; Wu, J.S.; Huo, F.W.: Skin Conformal and Antibacterial PPy-leather Electrode for ECG Monitoring. Advanced Electronic Materials, Vol. 6, No. 8, pp. 2000259, 2020.

[3] Xie, R.J.; Zhu, J.Y.; Wu, H.B.; Zhang, K.; Zou, B.H.; Zhang, X.Y.; Liang, J.Y.; Zheng, B.; Li, S.; Zhang, W.N.; Huang, W.; Wu, J.S.; Huo, F.W.: 3D-conductive Pathway Written on Leather for Highly Sensitive and Durable Electronic Whisker. Journal of Materials Chemistry C, Vol. 8, No. 28, pp. 9748-9754, 2020.

[4] Xie, R.J.; Hou, S.S.; Chen, Y.Y.; Zhang, K.; Zou, B.H.; Liu, Y.H.; Liang, J.Y.; Guo, S.H.; Li, H.F.; Zheng, B.; Li, S.; Zhang, W.N.; Wu, J.S.; Huo, F.W.: Leather-based Strain Sensor with Hierarchical Structure for Motion Monitoring. Advanced Materials Technologies, Vol. 4, No. 10, pp. 1900442, 2019.